Wiper Seals (Scraper Seals) at NewDealSeals

Wiper seals, sometimes referred to as scraper seals, play a critical role in machinery and equipment by acting as the first line of defense against contaminants. On this page, we’ll delve into the world of wiper seals, exploring their significance and how they contribute to the reliability and longevity of mechanical systems.

What Are Wiper Seals?

Wiper seals are essential components in machinery and equipment designed to perform a critical role: safeguarding precision. These seals act as formidable barriers against contaminants like dust, dirt, sand grains, and tiny metal particles, preventing them from infiltrating axially moving rods and plungers. By doing so, wiper seals prevent scratches, protect guiding elements, and extend the operational life of seals.

Advantages of Wiper Seals (Scraper Seals)

- Small Installation Grooves: Wiper seals are designed with small installation grooves, making them adaptable to various applications and sealing needs.

- Minimal Break-Out and Dynamic Sliding Friction: These seals are expertly crafted to minimize break-out and dynamic sliding friction, eliminating the risk of stick-slip. This ensures smooth and steady movement, even at low velocities, vital for precision machinery.

- Excellent Sliding Properties: Wiper seals exhibit outstanding sliding properties, contributing to the seamless operation of mechanical components.

- High Wear Resistance: Known for their exceptional wear resistance, wiper seals offer a prolonged service life, reducing maintenance requirements and enhancing equipment longevity.

- High Temperature Resistance: Wiper seals are engineered to withstand high temperatures, ensuring reliable performance in diverse operating conditions.

- Chemical Compatibility: These seals boast compatibility with a wide range of media due to the high chemical resistance of the rod sealing ring. Additionally, a comprehensive selection of O-ring compounds enhances their adaptability.

- Large Diameter Options: Wiper seals are available in diameters of up to a remarkable 1500 mm, catering to a broad spectrum of mechanical applications, including large-scale industrial machinery.

Technical Specifications

Type of movement

Rotary, reciprocating

Surface speed

≤ 4,0 m/s

Working temperature

Standard:-30 to +108°C

With FKM O-ring:-25 to +204°C

Standard materials Wiper

NDS-660, PTFE + 60% bronze

Standard materials O-Ring

NBR, FKM

Profiles Wiper Seals (Scraper Seals)

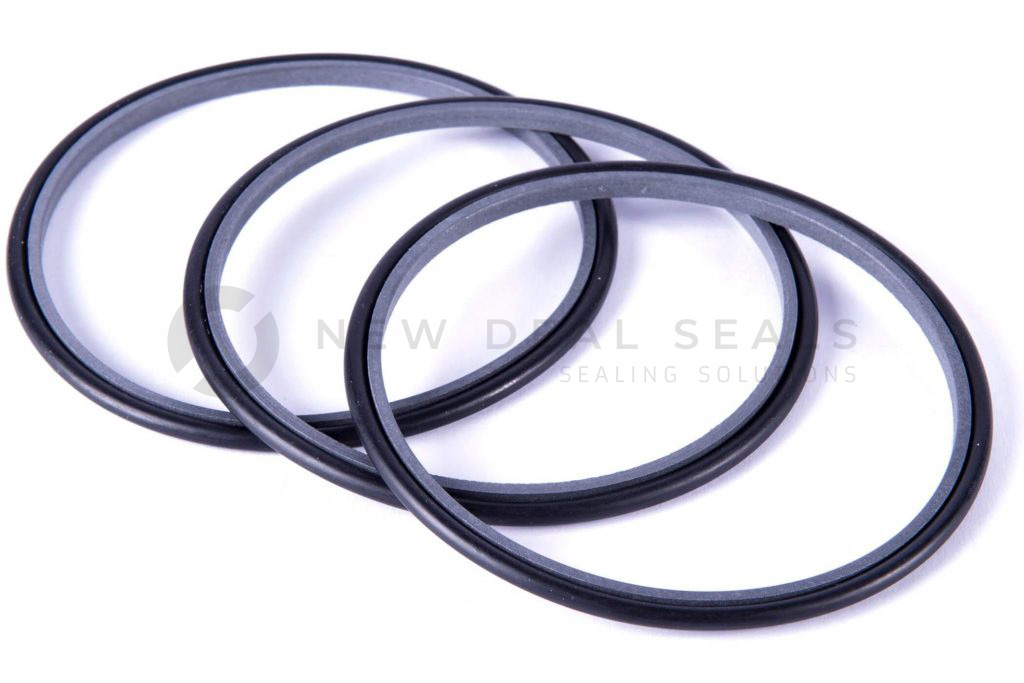

PROFILE W1

For double-acting

Profile W1 consists of a double-acting PTFE wiper ring and an O-ring as pretensioning element.

Capable of sealing dynamic pressure from both sides (bidirectional) at high pressure.

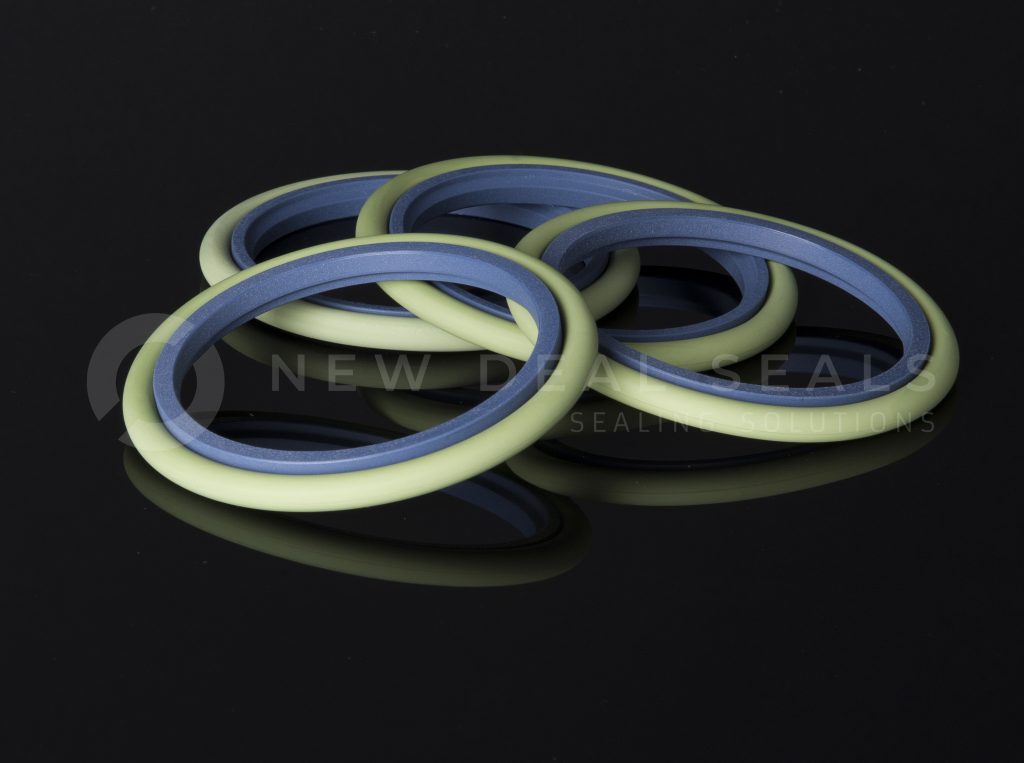

PROFILE W2

For single-acting

Profile W2 consists of a single-acting PTFE wiper ring and an O-ring as pretensioning element.

Economic price level.

PTFE COMPOUNDS

| Color | Temperature | Application | Information | |

|---|---|---|---|---|

| NDS-100 PTFE-virgin |

White | -190 to +230 °C | Chemical Industry, Food Industry | High chemical resistance Datasheet |

| NDS-123 PTFE +15% glass, +5% molybdenum disulfide |

Grey | -190 to +290 °C | Medium-duty | High chemical resistance, High creep resistance, Electrical properties like virgin PTFE Datasheet |

| NDS-225 PTFE +25% carbon |

Black | -190 to +315 °C | Pneumatics Rotary sealing | High wear and creep resistance Datasheet |

| NDS-235 PTFE +10% carbon fibre |

Black | -260 to +310 °C | Water hydraulics, Seawater, Short strokes with high frequency | Very good wear properties Datasheet |

| NDS-430 PTFE + 23% carbon + 2% graphite |

Black | -100 to +250 °C | Medium-duty, cold creep, thermal conductivity | Chemical and wear resistance Datasheet |

| NDS-555 PTFE + mineral fibers |

Antrachite | -200 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications | Chemical, wear and creep resistance Datasheet |

| NDS-640 PTFE +40% bronze |

Bronze | -156 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications |

Outstanding wear and creep resistance

|

| NDS-660 PTFE +60% bronze |

Bronze | -156 to +260 °C | Heavy mechanical stress, Hydraulic applications | Outstanding wear and creep resistance |

| NDS-750 PTFE + polyimide |

Tan | -260 to +310 °C | High speed rotating applications | Use against soft metals |

Related PTFE Seals

CONTACT FORM

We believe in the quality of our products and service. Fill out the form on the right-hand side and we will contact you shortly. Or you can use our product request form here.

NewDealSeals B.V.

+31 (0) 226 362 233

Boezemschop 8, Breekland, 1724 BJ Oudkarspel, The Netherlands