Guide Rings (Wear Rings) at NewDealSeals

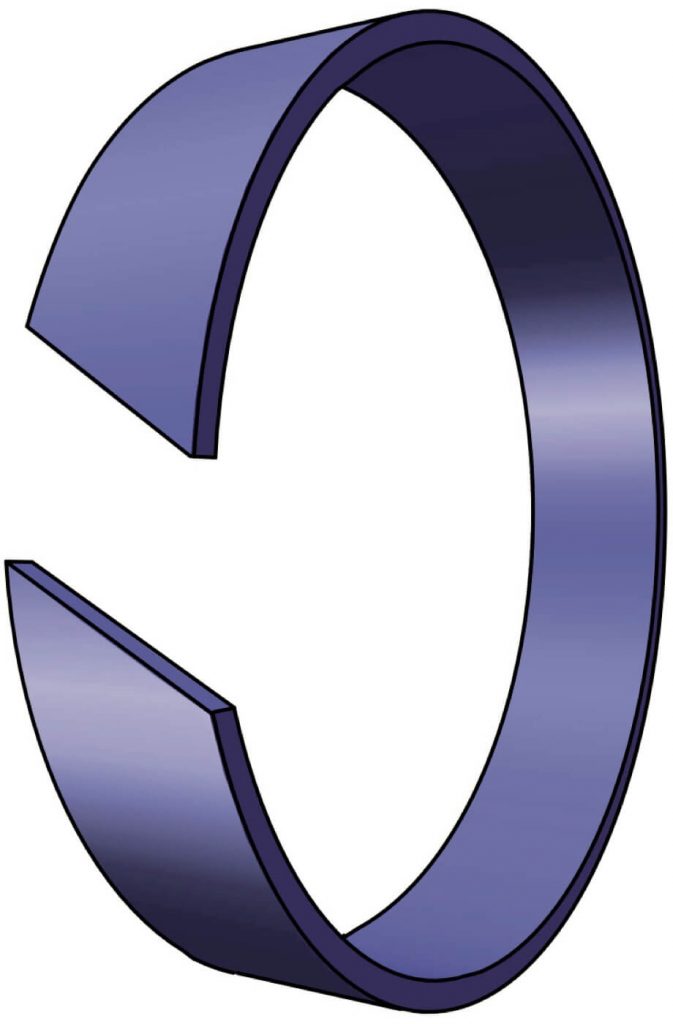

Guide rings, also known as wear rings, play an integral role in hydraulic cylinder systems, ensuring smooth and precise operation. Guide rings are the unsung heroes of hydraulic cylinder systems, facilitating metal-to-metal contact between moving components, such as the piston and the cylinder or the rod and the cylinder head. On this page, we’ll delve into the world of guide rings, unveiling their purpose, advantages, and why they are indispensable in the realm of sealing technology.

What are Guide Rings (Wear Rings)?

Guide rings, also known as wear rings, are crucial components in hydraulic cylinder systems. Their primary function is to guide the piston and rod while absorbing lateral forces. These rings facilitate metal-to-metal contact between moving parts within the cylinder, such as the piston and the cylinder wall or the rod and the cylinder head.

Advantages of Guide Rings

- High Load Capacity: Our guide rings exhibit remarkable bearing load capacity, ensuring robust performance even in demanding applications.

- Elimination of Stress Concentrations: These rings eliminate local stress concentrations, contributing to enhanced durability and reliability.

- Wear Resistance: Guide rings are engineered to resist wear, guaranteeing longevity and reducing maintenance costs.

- Low Friction: With a low coefficient of friction, these rings reduce energy loss and ensure smooth operation.

- No Stick-Slip: Even at low sliding speeds, guide rings exhibit no tendency to stick-slip, guaranteeing precise and steady movement.

- Versatile Dimensions: Available in practical dimensions, guide rings are adaptable to a wide range of hydraulic systems.

- Lubrication Versatility: Their profile geometry is ideally suited to work in lubricated air as well as dry and oil-free air, providing flexibility for various applications.

NewDealSeals supplies a wide range of guide rings as an economic alternative for e.g. Slydring® in HiMod®, Orkot® and Turcon® compounds.

Technical Specifications

Working Temperature

-100 to +200°C

Surface speed

≤ 10,0 m/s

Permissible specific load

At working temperature < 100°C: 2,5 N/mm2

Compounds Guide Ring

NDS-225, PTFE + 25% carbon

NDS-150, PTFE modified

Profiles Guide Rings

PROFILE G1

For pneumatic applications

G1 and G2 are used for bearings where it is imperative that the system pressure is carried on the seals. They are designed as open bearings with a well defined gap.

PROFILE G2

For hydraulic applications

G1 and G2 are used for bearings where it is imperative that the system pressure is carried on the seals. They are designed as open bearings with a well defined gap.

PROFILE G3

For hydraulic applications

G3 is a closed bearing, which in certain applications is used as a combined seal and bearing.

PTFE COMPOUNDS

| Color | Temperature | Application | Information | |

|---|---|---|---|---|

| NDS-100 PTFE-virgin |

White | -190 to +230 °C | Chemical Industry, Food Industry | High chemical resistance Datasheet |

| NDS-123 PTFE +15% glass, +5% molybdenum disulfide |

Grey | -190 to +290 °C | Medium-duty | High chemical resistance, High creep resistance, Electrical properties like virgin PTFE Datasheet |

| NDS-225 PTFE +25% carbon |

Black | -190 to +315 °C | Pneumatics Rotary sealing | High wear and creep resistance Datasheet |

| NDS-235 PTFE +10% carbon fibre |

Black | -260 to +310 °C | Water hydraulics, Seawater, Short strokes with high frequency | Very good wear properties Datasheet |

| NDS-430 PTFE + 23% carbon + 2% graphite |

Black | -100 to +250 °C | Medium-duty, cold creep, thermal conductivity | Chemical and wear resistance Datasheet |

| NDS-555 PTFE + mineral fibers |

Antrachite | -200 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications | Chemical, wear and creep resistance Datasheet |

| NDS-640 PTFE +40% bronze |

Bronze | -156 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications |

Outstanding wear and creep resistance

|

| NDS-660 PTFE +60% bronze |

Bronze | -156 to +260 °C | Heavy mechanical stress, Hydraulic applications | Outstanding wear and creep resistance |

| NDS-750 PTFE + polyimide |

Tan | -260 to +310 °C | High speed rotating applications | Use against soft metals |

Related PTFE Seals

CONTACT FORM

We believe in the quality of our products and service. Fill out the form on the right-hand side and we will contact you shortly. Or you can use our product request form here.

NewDealSeals B.V.

+31 (0) 226 362 233

Boezemschop 8, Breekland, 1724 BJ Oudkarspel, The Netherlands