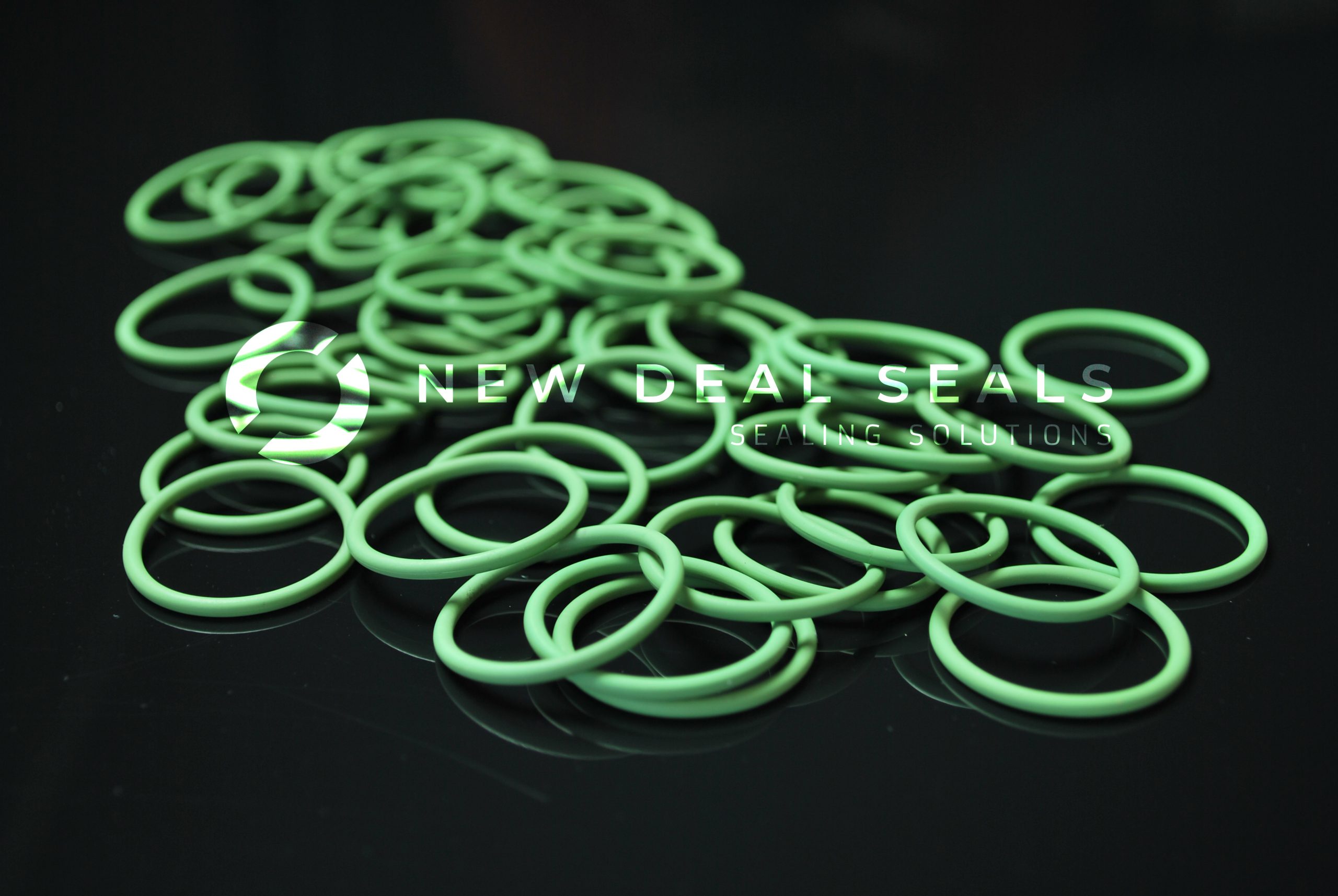

FKM (Viton) O-Rings at NewDealSeals

FKM O-rings, commonly known as Viton O-rings, have earned a reputation as a top choice for sealing applications across diverse industries. With exceptional resistance to heat, chemicals, and extreme conditions, FKM O-rings are engineered to deliver superior sealing performance. On this page, we’ll explore the key benefits of FKM (Viton) O-rings and why they are the preferred choice for critical sealing needs.

What are Viton O-Rings?

Viton O-rings, also known simply as FKM (Fluorocarbon O-rings), are a type of synthetic rubber sealing component widely used for creating reliable seals in various industrial applications. Viton is a trade name for fluoroelastomer materials developed and manufactured by The Chemours Company, formerly a part of DuPont. These O-rings are recognised for their exceptional chemical resistance, high-temperature tolerance, and robust sealing capabilities.

General properties FKM (Viton) O-Rings

Temperature range:

Shore:

Relative cost

Tradenames:

Common names:

Colours available:

-24 to 204 °C

30 / 40 / 50 / 60 / 70 / 80 / 90

◍◍◍◍◍

DAI-EL® (Daikin Industries), Dyneon® (3M), Tecnoflon® (Solvay), Viton® (DuPont)

FKM, Fluorelastomer, FPM, Fluoropolymer

Black, Brown, Green. Other colors on request.

Why choose FKM (Viton) O-Rings?

FKM O-rings (also Viton O-rings) are an excellent choice for general use due to their exceptional resistance to chemicals, oils and extreme temperatures (-25 to 204 °C). Special compounds can further reduce the low temperature threshold to -30 °C for dynamic seals and about -40 °C in static applications.

Key characteristics and features of Viton O-rings include:

- Chemical Resistance: Viton O-rings have outstanding resistance to a wide range of chemicals, including acids, bases, fuels, solvents, and oils. This resistance makes them suitable for use in environments where exposure to aggressive chemicals is common.

- High Temperature Tolerance: Viton O-rings can withstand elevated temperatures ranging from approximately -20°C (-4°F) to 200°C (392°F) or even higher with special formulations. This high-temperature resistance makes them ideal for sealing applications in engines, industrial equipment, and other high-heat environments.

- Oil and Fuel Resistance: They exhibit excellent resistance to oils, fuels, and lubricants, making them a preferred choice for sealing components in automotive and aerospace applications.

- Low Compression Set: Viton O-rings maintain their shape and sealing effectiveness over time due to their low compression set properties. This characteristic ensures that the seals continue to perform reliably and reduce the need for frequent maintenance or replacement.

- Versatility: Viton O-rings come in various sizes, shapes, and durometers (hardness levels), allowing for customization to meet specific sealing requirements in diverse industries.

- Wide Range of Applications: These O-rings find applications in numerous industries, including automotive, aerospace, chemical processing, oil and gas, pharmaceuticals, and more. They are commonly used in sealing critical components, such as gaskets, valves, pumps, and hydraulic systems.

- Regulatory Compliance: Viton materials can meet industry-specific standards, such as FDA compliance for use in food-related applications or certifications for use in the pharmaceutical and medical sectors.

In summary, Viton O-rings are highly versatile and reliable sealing solutions known for their exceptional chemical resistance and temperature tolerance. They play a critical role in ensuring the integrity and performance of equipment and machinery in various industrial settings, where reliable seals are essential for safety, efficiency, and environmental protection.

FKM performs well in:

- Acids

- Fuels

- Petroleum products

- Silicone fluids & greases

- Solvents

FKM does not perform well in:

- Amines

- Hot chlorosulfonic acid

- Ketones

- Low molecular weight esters & ethers

- Fireproof hydraulic fluids (e.g. Skydrol®)

Typical FKM Applications:

- High temperature seals

- Fuel and chemical resistant hoses

- Oil and fuel seals

Certifications & compliances

Newdealseals offers a wide range of products & materials that are certified and/or in compliance with industry specific standards. Examples of certifications and compliances:

Food

FDA CFR 21.177.2600 (A-D) Dry foods

FDA CFR 21.177.2600 (A-F) Fatty foods

EC 1935/2004 compliance

EC 2023/2006 compliance

BFR Class XV

Medical

USP class VI

ISO 10993

NSF 61 section 6

Oil & Gas

Norsok M710

Drinking water

WRAS

3-A

Gas appliances

DIN EN 549

Alternatives for FKM O-Rings or Viton O-Rings

Do you want improved low temperature properties?

VMQ, Silicone O-Rings

Temperature range (-54 to 232 °C). Very suitable for mineral oils. Good flexibility, low compression set, ozone and UV-resistant.

Do you want better overal chemical resistance & higher temperature resistance?

FFKM, Fluorezi® O-Rings

Temperature range (-30 to 325 °C). Superior chemical resistance to meet the most critical requirements.

CONTACT FORM

We believe in the quality of our products and service. Fill out the form on the right-hand side and we will contact you shortly. Or you can use our product request form here.

NewDealSeals B.V.

+31 (0) 226 362 233

Boezemschop 8, Breekland, 1724 BJ Oudkarspel, The Netherlands