Metallic Seals

Metallic seals are designed to make a seal by means of a ‘first line contact’ or ‘wedge action’ between the counter face (e.g. a flange) and the packing. The pressure on the sealing surface, exerted by the bolts, causes the ‘softer’ metal of the packing to flow into the microscopic structure of the harder flange material, thus creating an extremely strong and efficient seal.

Metallic seals are either made of one single metal or a combination of metals. In order to guarantee a proper, reliable seal, it is crucial to make the right choice of profiles and material.

Products

Bonded Seals | Dowty Washers

Bonded seals are static seals that are used to seal bolt heads, nuts and screw and flange connections.

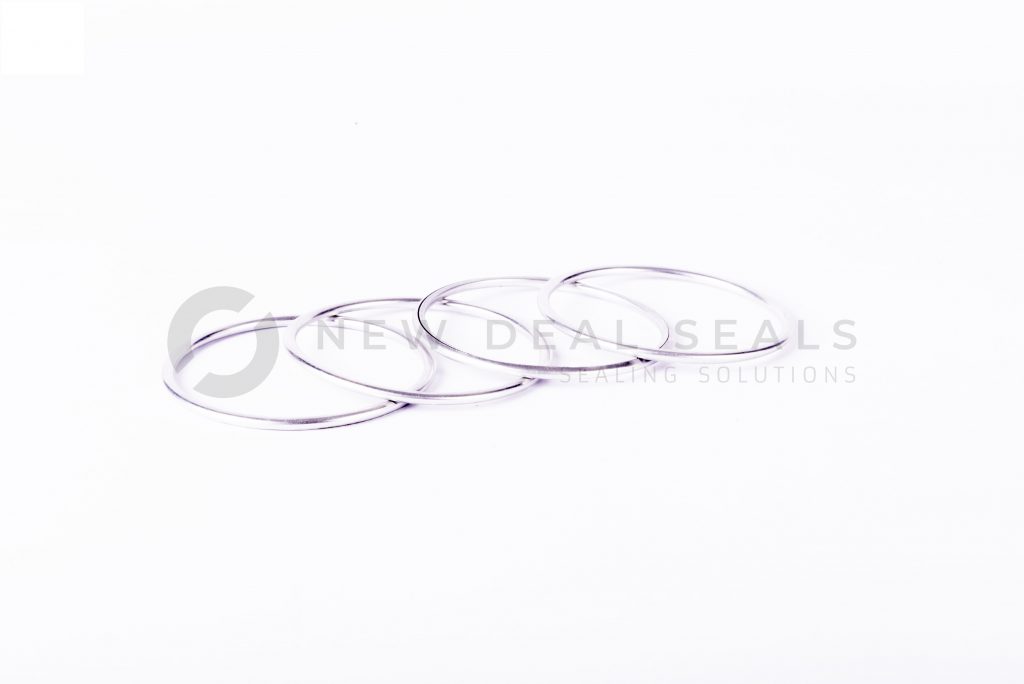

Metal Sealing Rings

Metallic seals are designed to make a seal by means of a ‘first line contact’ between the counter face and the packing.

Metallic Materials

NewDealSeals supplies metallic seals in more than 100 different materials. To simplify assembly, or to improve the sealing properties, the surfaces of our seals can be given various finishes, such as bronze, chromium, Dacromet®, eloxal, phosphated, gold, copper, brass, nickel, tin, wax, silver or zinc.

NewDealSeals metallic seals are available in accordance with various standards (e.g. DIN7603, 2690, 2691, 2697, EN837-2). The metallic materials are subdivided into the following metal types:

- Aluminium

- Armco

- Bronze

- Hastelloy®

- Inconel

- Copper

- Lead

- Brass

- Monel

- Nickel

- Steel (SS, spring steel)

- Silver

- Zinc

Contact Expert

CLIENT CASES

With more than 25 years experience in the sealing industry our engineering department is ready for your sealing challenge. Below you can find a small range of our engineering expertises/services.

► Knowlegde of all sealing types

► FEM analysis capabilities

► 3D design department

► Material laboratory

► Prototype machining equipment

► 3D ”rubber” printing options

► Custom made reverse engineering equipment

1. PERFECT SEALING SURFACE

2. O-Rings Class A+

3. Oil Reduction Rod Seal Improvement

4. One piece Oil Seal Design

CONTACT FORM

We believe in the quality of our products and service. Fill out the form on the right-hand side and we will contact you shortly. Or you can use our product request form here.

NewDealSeals B.V.

+31 (0) 226 362 233

Boezemschop 8, Breekland, 1724 BJ Oudkarspel, The Netherlands