Spring-Energized Seals: SYNERINGS® – At NewDealSeals

In the realm of sealing solutions, there’s a revolutionary concept that stands tall when faced with extreme demands like high temperatures, aggressive mediums, and challenging environments. Say hello to SYNERINGS® – an advanced sealing system that redefines what’s possible in the world of sealing technology. It’s the ultimate solution for conditions where conventional sealing compounds, such as elastomers, PUR, and fabric materials, fall short.

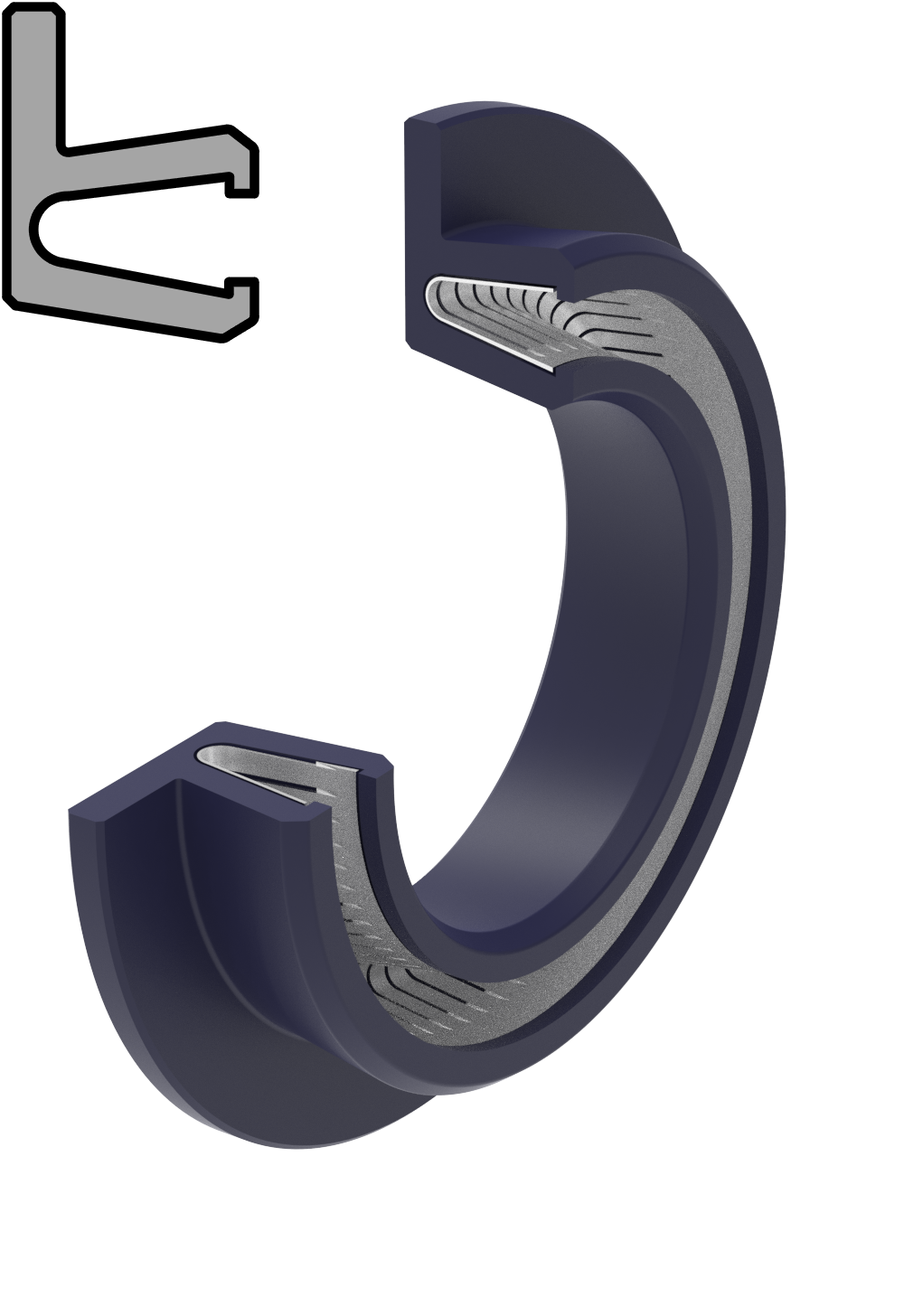

At its core, SYNERINGS® leverages the remarkable properties of PTFE (Polytetrafluoroethylene), a material renowned for its exceptional thermal and chemical resistance. However, PTFE’s inherent lack of elasticity posed a challenge, until the inception of SYNERINGS®. This innovative system ingeniously combines a specially modified PTFE component with an energizing spring, typically crafted from stainless steel. The result? An unbeatable sealing solution that maximizes the extraordinary qualities of PTFE to their full potential.

Spring-Energized Seals: SYNERINGS® – At NewDealSeals

In the realm of sealing solutions, there’s a revolutionary concept that stands tall when faced with extreme demands like high temperatures, aggressive mediums, and challenging environments. Say hello to SYNERINGS® – an advanced sealing system that redefines what’s possible in the world of sealing technology. It’s the ultimate solution for conditions where conventional sealing compounds, such as elastomers, PUR, and fabric materials, fall short.

At its core, SYNERINGS® leverages the remarkable properties of PTFE (Polytetrafluoroethylene), a material renowned for its exceptional thermal and chemical resistance. However, PTFE’s inherent lack of elasticity posed a challenge, until the inception of SYNERINGS®. This innovative system ingeniously combines a specially modified PTFE component with an energizing spring, typically crafted from stainless steel. The result? An unbeatable sealing solution that maximizes the extraordinary qualities of PTFE to their full potential.

How SYNERINGS® Works:

- SYNERINGS® is precision-crafted from a unique PTFE compound, tailor-made to excel in the most demanding conditions.

- An energizing spring, often constructed from stainless steel, provides the necessary resilience to achieve a reliable and highly effective seal.

- Upon installation in the seal gland, SYNERINGS® undergoes radial or axial compression. The resilient spring responds with a constant force, extending the sealing lips. As system pressure comes into play, the seal gains additional energization, bolstering the sealing force.

In dynamic applications, the spring expands to compensate for seal wear while maintaining the essential load. Even in scenarios marked by thermal cycling, the spring remains steadfast in energizing the seal lips, all without suffering a compression set or becoming excessively soft or hard.

NewDealSeals proudly offers a wide array of spring-energized seals, including the groundbreaking SYNERINGS®, providing an economical yet high-performance alternative to established brands like Balseal®, Flexiseal®, Omniseal®, and Variseal®.

TECHNICAL SPECIFICATIONS

OPERATING TEMPERATURES

Synerings® with V-spring: -150 to + 225°C

Synerings® with O-spring: -150 to + 260°C

OPERATION VELOCITIES

Synerings® with V-spring

Reciprocating: 15-20 m/s

Helical and rotating: ≤ 4 m/s

Synerings® with O-spring

Reciprocating: 15-20 m/s

Helical and rotating: ≤ 4 m/s

PRESSURE LIMITS

Synerings® with V-spring: ≤ 350 bar

Synerings® with O-spring: ≤ 800 bar

PROFILES

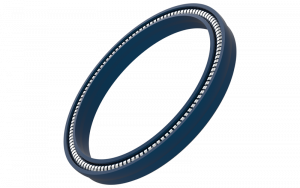

PROFILE S1

Rotating

The profile S1 consists of a PTFE sealing ring with a V-spring. The profile S1 is appropriate for rotating applications as an alternative to an O-ring in situations where sealing performance and friction have to be optimized.

PROFILE S2

Dynamic rod sealing

The profile S2 consists of a PTFE sealing ring with a V-spring. The profile S2 is appropriate for dynamic rod sealing applications as an alternative to an O-ring in situations where sealing performance and friction have to be optimized.

PROFILE S3

Dynamic piston sealing

The profile S3 consists of a PTFE sealing ring with a V-spring. The profile S3 is appropriate for dynamic piston sealing applications as an alternative to an O-ring in situations where sealing performance and friction have to be optimized.

PROFILE S4

Static inside sealing

The profile S4 consists of a PTFE sealing ring with an O-spring. The profile S4 is appropriate for static inside sealing applications as an alternative to an O-ring in situations where sealing performance has to be optimized.

PROFILE S5

Static outside sealing

The profile S5 consists of a PTFE sealing ring with an O-spring. The profile S5 is appropriate for static outside sealing applications as an alternative to an O-ring in situations where sealing performance has to be optimized.

PROFILE S6

Flange sealing: internal pressure

The profile S6 consists of a PTFE sealing ring with an O-spring. The profile S6 is appropriate for flange sealing applications with internal pressure as an alternative to an O-ring in situations where sealing performance has to be optimized.

PROFILE S7

Flange sealing: external pressure

The profile S7 consists of a PTFE sealing ring with an O-spring. The profile S7 is appropriate for flange sealing applications with external pressure as an alternative to an O-ring in situations where sealing performance has to be optimized.

PTFE COMPOUNDS

| Color | Temperature | Application | Information | |

|---|---|---|---|---|

| NDS-100 PTFE-virgin |

White | -190 to +230 °C | Chemical Industry, Food Industry | High chemical resistance Datasheet |

| NDS-123 PTFE +15% glass, +5% molybdenum disulfide |

Grey | -190 to +290 °C | Medium-duty | High chemical resistance, High creep resistance, Electrical properties like virgin PTFE Datasheet |

| NDS-225 PTFE +25% carbon |

Black | -190 to +315 °C | Pneumatics Rotary sealing | High wear and creep resistance Datasheet |

| NDS-235 PTFE +10% carbon fibre |

Black | -260 to +310 °C | Water hydraulics, Seawater, Short strokes with high frequency | Very good wear properties Datasheet |

| NDS-430 PTFE + 23% carbon + 2% graphite |

Black | -100 to +250 °C | Medium-duty, cold creep, thermal conductivity | Chemical and wear resistance Datasheet |

| NDS-555 PTFE + mineral fibers |

Antrachite | -200 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications | Chemical, wear and creep resistance Datasheet |

| NDS-640 PTFE +40% bronze |

Bronze | -156 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications |

Outstanding wear and creep resistance

|

| NDS-660 PTFE +60% bronze |

Bronze | -156 to +260 °C | Heavy mechanical stress, Hydraulic applications | Outstanding wear and creep resistance |

| NDS-750 PTFE + polyimide |

Tan | -260 to +310 °C | High speed rotating applications | Use against soft metals |

Related PTFE Seals

CONTACT FORM

We believe in the quality of our products and service. Fill out the form on the right-hand side and we will contact you shortly. Or you can use our product request form here.

NewDealSeals B.V.

+31 (0) 226 362 233

Boezemschop 8, Breekland, 1724 BJ Oudkarspel, The Netherlands