For the past few weeks, team LEA has been busy conducting “cold flow tests” to check for any signs of malfunction. Cold flow tests are in simple terms, a test of a liquid rocket without firing it to check or verify the integrity of a propulsion subsystem, and to provide for the conditioning and flow of propellants (including tank pressurization, propellant loading, and propellant feeding).

We are glad to share that the NewDealSeals’ Synerings have passed every single time!

Check out the video below to see that testbench in action:

WHAT IS PROJECT LEA?

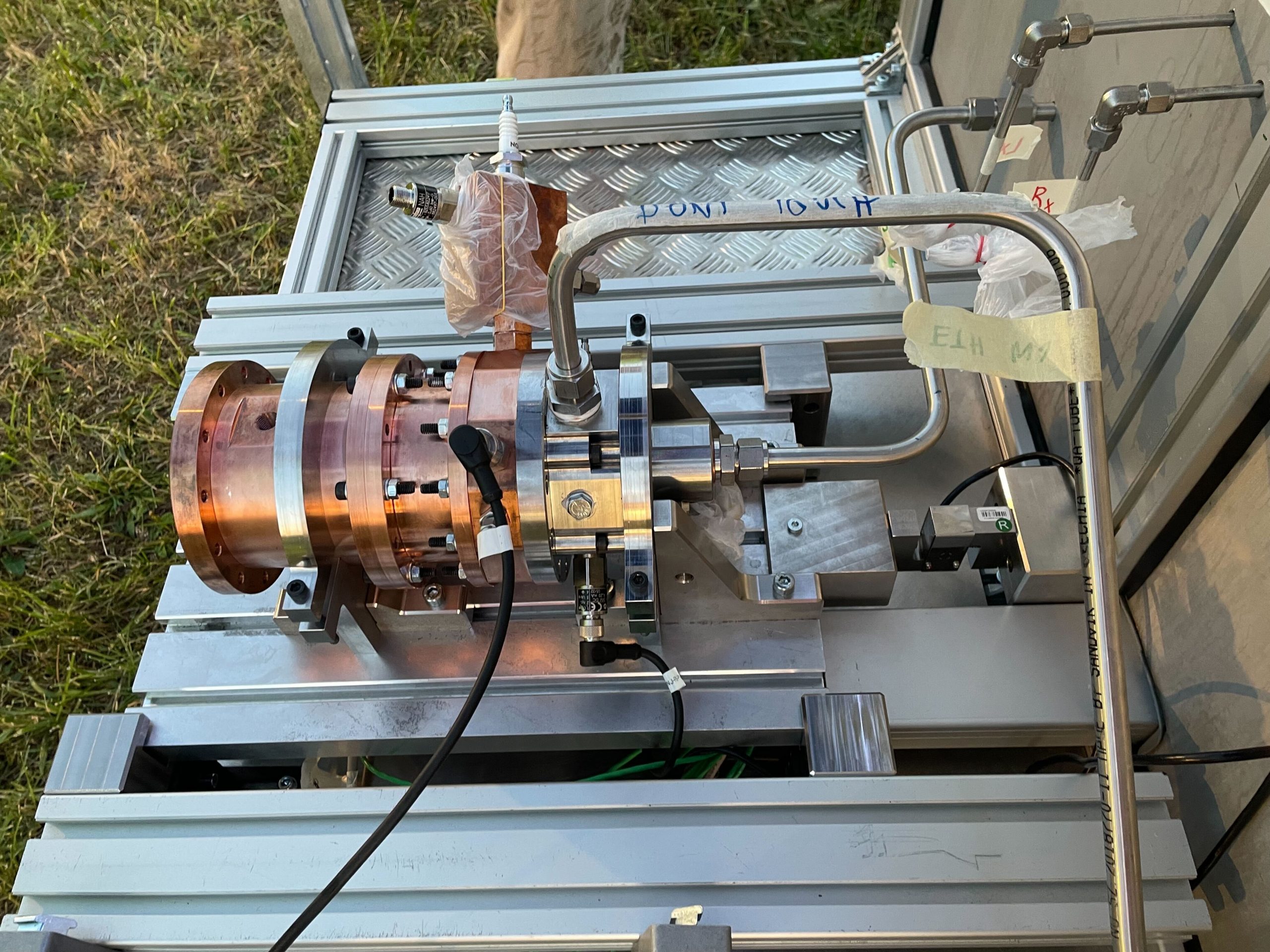

LEA stands for Liquid Engine Aris. In order to make testing more efficient, team LEA has built a modular and versatile testbench. The test bench is fixed to a trailer allowing them to test directly on the airfield in Dübendorf. This will not only save time, but also transport costs – making the firing cycles during the testing phase faster and hence enabling more efficient research. This will benefit the team, but also for future ARIS projects.

Withstand forces up to 1.5 KN, the testbench is suitable for smaller rocket engines with focus on academic research. Thanks to its modularity, the testbench is compatible not only with liquid but hybrid rocket engines as well – bringing testing to a whole new level.

PROPELLANT SUPPLY SYSTEM

The propellant supply system (PSS) supplies the engine with liquid fuel and liquid oxidizer. For each liquid a separate run tank is designed and pressurised with nitrogen as an inert gas. In addition, a purge and draining system is designed to ensure a clean system for every firing. The valves will be controlled remotely.

Bioethanol is used as fuel because it offers a good balance between performance, availability and easy handling. For the oxidizer, liquid oxygen (LOX), was chosen as this is space industry standard. The main challenge here is the cryogenic nature of latter. It requires additional safety measures and extra care while handling. For this strict oxygen compatibility and prior cleaning for oxygen service have to be ensured. Moreover, shielding walls are installed to ensure the separations of the two propellant components at all times and protect our supply system.

NEWDEALSEALS CONTRIBUTION

NewDealSeals sponsored team LEA with 20 Synerings. These Synerings (as seen as the white ring on the photo above) are made out of PTFE virgin and Elgiloy. Fun fact: the same metal has been used for certain parts of the infamous Lockheed SR-71 “Blackbird” thanks to its superior mechanical properties. The requirements of the seal are listed below:

Temperature range: -170°C to 230°C

Pressure: 25 Bar

Chemical resistance: bioethanol and liquid oxygen

The NewDealSeals’ engineering team took these parameters and were able to engineer the solution within days. And to no surprise, the seals passed every test without failure!

For more info about our Synerings® please visit our website: https://i-seals.nl/spring-energized-seals-synerings/